+91 8976926950

response@eurosiliconehoses.com / enquiry@eurosiliconehoses.com

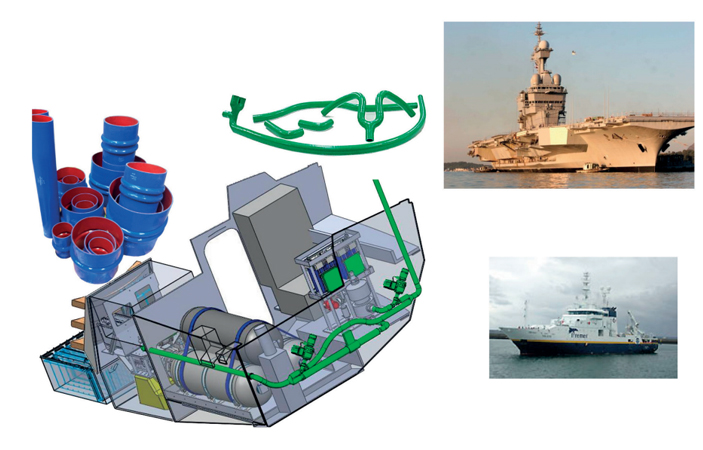

Marine Rubber Hoses

Marine Hose Pipe, Marine Silicone Rubber Hoses Manufacturer in India, France

Silicone Hoses, Exhaust Air Hoses

SAE J 2006 - ISO 8862:1987

Our EEMI marine hoses Meets multiple industry and government standards

Black nitrile protect oil resistance in marine environments

EEMI offers complete line offshore marine hoses. The hoses are manufactured by highly skilled workforce in state-of-the-art facilities in India and France.

EEMI is one amongst the leading quality rubber manufacturer in India. At EEMI brand industrial hoses are produced from the best quality of natural and artificial rubber generally meeting all aspects and specifications. Hoses manufactured at EEMI find wide spectrum of application covering most sorts of industries like petrochemical, cement, fertilizers, textiles, marine, food processing, pharmaceuticals, oil & gas industry, bulk material handling, construction etc.

At EEMI manufacturing of marine hoses are totally optimized with the fitment of customized end connection under the identical roof: the ultimate testing of the whole hose assembly in-house ensures trouble free operation at the applying site.

We EEMI are into manufacturing of Marine Rubber hoses for the past years, we've major supplies made to the Rubber Hoses for Chemical, Rubber Hoses for Mining and Dredging Industry, Rubber Hoses for Cement and ash, Rubber Hoses with Flange connections, Rubber Hoses for Dewatering, Rubber Hoses for Oil and Gas Industry, Rubber Hoses and Rubber Bellows, Rubber Hoses with Couplings, our expertise are into the designing of rubber hoses in large dia. together with unique end connections to suit client’s requirements.

we've got an in house complete inspection facility and also host inspection for various project work.

EEMI marine hose features innovative design and use of superior-performance materials, and meets or exceeds more marine industry standards than the other hose.

It is highly versatile for a myriad of applications including pump intake, discharge and ventilation; cabin heating; coolant and radiator service; gasoline and diesel oil systems; lubrication systems; wet-exhaust systems.

Offshore marine hose provides service for marine potable water systems. Specially blended materials won't impart taste or odor to water.

Marine offshore hoses are conduit-tubular structures used for loading, discharging, transferring and transporting fluid products like oil, gas, and water. These marine hoses conduits are applied within the offshore industry by utilising novel marine materials and sustainable technologies. supported sustainability, there are advances made as solutions for challenging environments. These challenges include scouring gases, problem regions, changing sea water temperatures, platform loads and vessel motions.

This paper reviews historical timeline and patent development of offshore marine hoses within the marine environment. The review also discusses the evolutions within the hose designs, potentials of the hoses, Comprehensive discussions with necessary recommendations are made for fluid applications within the offshore industry.

Reinforcement: Many hoses have reinforcement within the walls for strength and rigidity, and to stop collapse or expansion struggling.

Strength:

Marine Hose used for discharge lines should resist pressure. This so called burst strength, measured in pounds per sq in (psi) depends on product design and diameter; small diameter hoses have greater burst strengths. Hose with multiple plies or helical reinforcement has greater pressure limits, which is vital for pressurized water or exhaust applications.

Vacuum rating : Off shore hose on the intake side must withstand suction, a property that's measured with a so called vacuum rating.

Intake Marine hose should have a vacuum rating of 20 or higher.

Temperature range : Mostly critical for engine cooling hose, but may additionally be important for pressurized quandary systems.

Hose utilized in potable (drinking) water systems must be constructed from safe, non-toxic materials that are contamination- and corrosion-free.

Bend radius : for correct installation a hose shouldn't be bent quite the minimum bend radius recommended by the manufacturer to avoid kinks and breakage. Especially important for sewage lines and pump applications.

EEMI provides complete solutions, tailored to individual applications from start to end.

Our years of experience in marine applications mean that we will offer expert advice in the slightest degree phases of a brand new development project. Engineering includes transfer of know the way, production of prototypes, optimisation of components for series production, performance of tests and approval procedures and detailed documentation.

Marine Hose :

Marine offshore Hoses, steel cord reinforced, are hoses coming from the EEMI Company’s long experience within the offshore industry.

The hoses are manufactured for offshore Moorings.

Marine components are often exposed to harsh conditions, like moisture, salt, ozone, and sunlight, so it’s crucial that these components are robust enough to keep up optimum function in such a rigorous service environment.

Our experts can conduct standard testing protocols or design custom programs for marine hoses and fluid transfer assemblies of every kind Marine offshore hoses.