+91 8976926950

response@eurosiliconehoses.com / enquiry@eurosiliconehoses.com

Aerospace and Performance Hoses

Aerospace and Performance Hoses, Aeroquip aircraft hose Manufacturer in India, France

Aerospace fluid systems needs hose assemblies that perform well stressed and supply years of reliable service. Our Aerospace hose assemblies are constructed with seamless, smooth-bore inner tubes for optimum flow and include a skinny layer of carbon to eliminate static charge buildup. Along with stainless-steel for durability and wear resistance, EEMI Products PTFE materials are designed to resist all aircraft fuel, oil, coolants, and solvents. additionally, they feature a limitless period of time.

We EEMI are manufacturers, exporters and suppliers of best quality performance aerospace hoses. By years of aerospace engineering experience and style capabilities, our PTFE hoses will provide the performance you wish with the reliability you expect. Airplane engines must work without fail. Unlike engines on the bottom where a failure may be more forgiving, an airplane engine isn't allowed to fail, or within the rare event that it does, the backup engine must work. Aerospace Silicone hoses and tubing are employed in airplane engines due to their reliability and dependability.

Silicone hoses are strong, which suggests they'll delay within the high-vibration and high-speed operating conditions of aircraft engines. These hoses also perform well under extreme climate, making them the correct choices for flying machinery at high elevations where temperatures drop quickly.

In Other Aircraft Systems, These hoses are suitable for other airplane systems moreover, for the explanations explained above further as some others. One main reason they work so well in aircraft systems is that they'll withstand the changes in pressure that are experienced because the plane flies to different elevations.

We want to denote that EEMI Aerospace hoses may be utilized in helicopters and gliders, too. In Air engines Aerospace hoses can easily be clamped into place so they are doing not move or slip away. This makes them a good choice for space exploration probes and satellites. Once they're put into place, there shouldn’t be a difficulty with the hoses or tubing being jostled out of place. this is the reason what we’ve already discussed for aircraft applications, namely, the reliable performance under high-vibration, high-speed environments, the flexibility to resist cold and warmth extremes, and therefore the ability to stay intact under varying pressures, and you've got an excellent design component for a good range of space and satellite applications.

Before you finalize your design, we’d like to talk with you to determine if what you’re building will work well with our hoses. we'll allow you to know which silicone hoses and tubing products are best for your particular application, and if there are any concerns, we are able to usually customize an answer.

Many of our clients collaborate with us on their unique designs, and together, we come up with the simplest possible configurations that fit within their budgets. If you’d prefer to learn more about how silicone hoses can feature in your aircraft and space applications, reach resolute the knowledgeable technical team at EEMI.

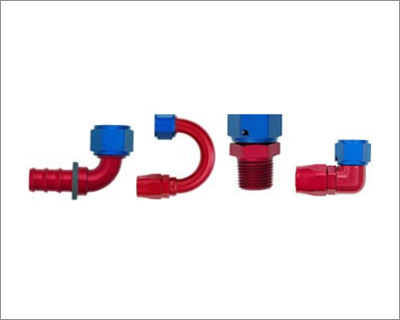

Stainless Steel Hoses, PTFE SS Braid, Aluminum, Carbon Steel, Nylon, ARAMIDE, Fire resistant.

Our Know Haw, is make Assembled Flexible Hoses, According The USA and European.

Aerospace Specifications For : Hydraulic, Brakes liquids, Kerosene , petrol , oil transfer…

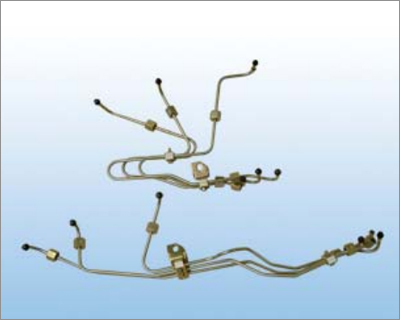

We produce Formed Metal tubes : Titanium, Stainless steel, Aluminum, Steel, etc…

Group certified: ISO 9001‐2000 and UN 9100. We Have Facility’s in FRANCE, Spain,U.K, INDIA,

MEXICO .